Professional M35 HSS-E Spiral Flute Tap Set, OH Limit, TiN Coated for Stainless Steel, Aluminum & Copper

- High-Performance M35 Cobalt Steel & TiN Coating Made from premium M35 HSS-E steel with 5% cobalt for superior hardness and heat resistance. Enhanced by gold Titanium Nitride (TiN) coating, it reduces friction and can significantly extend tool life depending on material and cutting conditions. Ideal for stainless steel, copper, cast aluminum, and alloy steel.

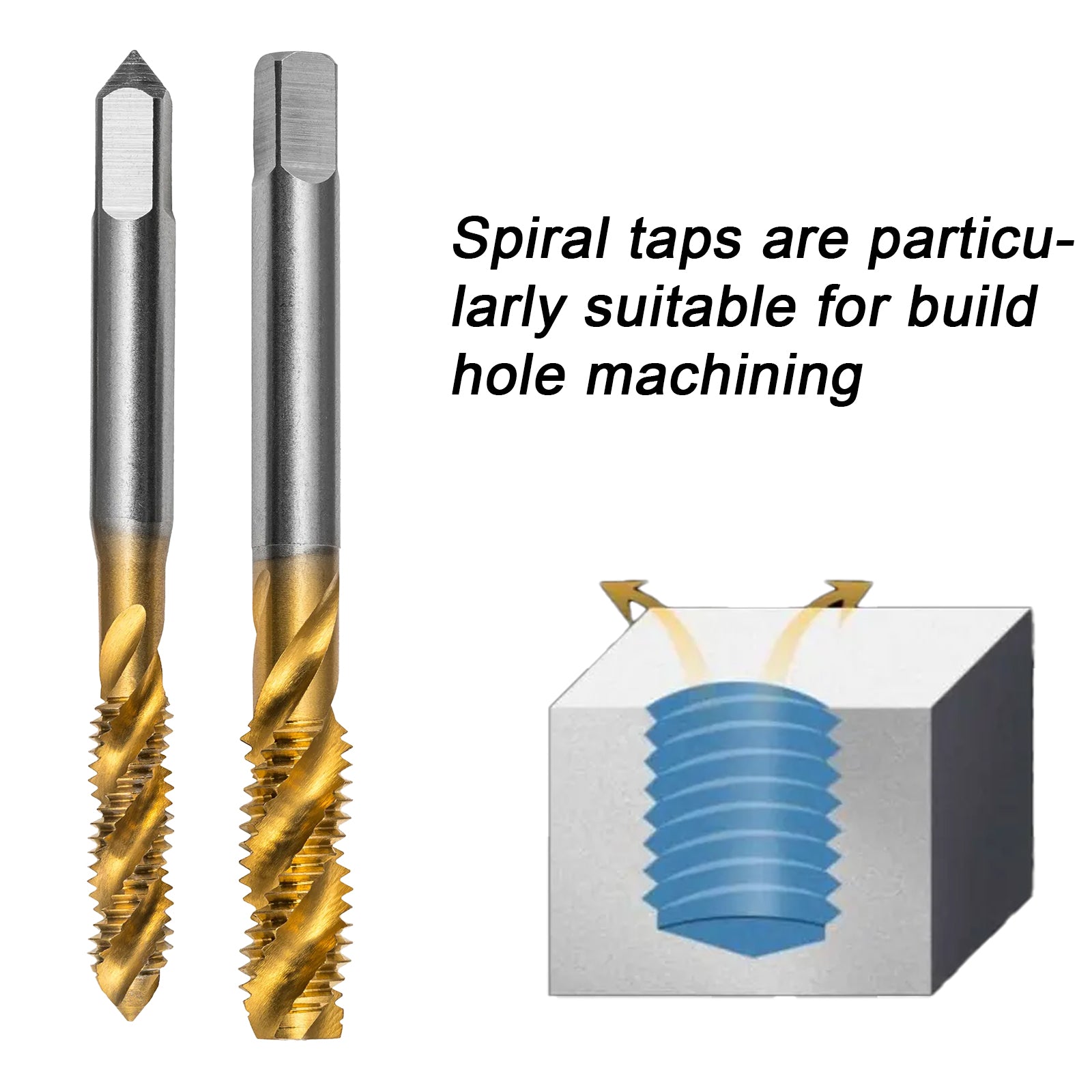

- Optimized for Blind Holes with Efficient Chip Evacuation The 40° spiral flutes design excels in blind hole threading, rapidly evacuating chips upward to prevent clogging. Designed for blind holes; for through holes, consider alternative flute geometries.

- Precision OH Limit for Reliable Thread Quality Engineered to OH limit (Unified Thread Standard), this tap ensures precise thread engagement for bolts and fasteners in both soft and hard materials. Perfect for industrial machining, automotive repair, and DIY projects demanding consistent accuracy.

- Versatile for Multi-Material Machining Excels in cutting stainless steel, softer titanium alloys, copper, cast aluminum, and plastics. The TiN coating resists adhesion and corrosion, making it suitable for wet or dry environments. A top choice for high-speed CNC operations and manual repairs.

Pairs well with

Professional M35 HSS-E Spiral Flute Tap Set, OH Limit, TiN Coated for Stainless Steel, Aluminum & Copper

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays.

-

Shipping Information

Use this text to answer questions in as much detail as possible for your customers.

-

Customer Support

Use this text to answer questions in as much detail as possible for your customers.

-

FAQ’s

Use this text to answer questions in as much detail as possible for your customers.

-

Contact Us

Use this text to answer questions in as much detail as possible for your customers.

PRODUCT HIGHLIGHTS

- Made from premium HSS-E, the taps undergoes rigorous heat treatment and specialized coating processes. This not only ensures exceptional wear resistance but also greatly enhances its stability under high-load and high-temperature conditions.

- Its unique spiral cutting angle and optimized feed design ensure smooth chip evacuation, reducing cutting resistance and heat generation. This effectively guarantees high precision and dimensional stability for every internal thread.

- The optimized spiral groove structure quickly removes metal chips, boosting processing speed and reducing vibrations and abnormal wear, thereby providing technical support for low-cost, high-efficiency production.

- Specially designed for stainless steel, aluminum, and other metal materials, whether for manufacturing precision components or mass production, this taps consistently delivers high-quality thread forming, meeting the needs of various industries.

APPLICATION SCENARIOS

- Machinery Manufacturing & Automation Equipment

In critical areas such as precision components and transmission systems, the spiral taps produces high-standard internal threads, ensuring precise assembly of parts and enhanced overall machinery stability.

- Automotive and Aerospace

Designed for high-strength materials and demanding machining environments, the JIANXING spiral taps maintains excellent cutting performance even under high-temperature and high-load conditions, offering reliable support for the production of key automotive and aerospace components.

- Home Appliances & Electronics

In sectors like home appliances and communication devices, precise and reliable threaded connections are crucial. The excellent design of this spiral taps ensures thread precision at every point, reducing equipment failure rates.

- Maintenance & Custom Equipment

Beyond mass production, the spiral taps also plays a crucial role in engineering repairs, equipment upgrades, and small-batch custom machining, providing efficient solutions for various maintenance and upgrade needs.