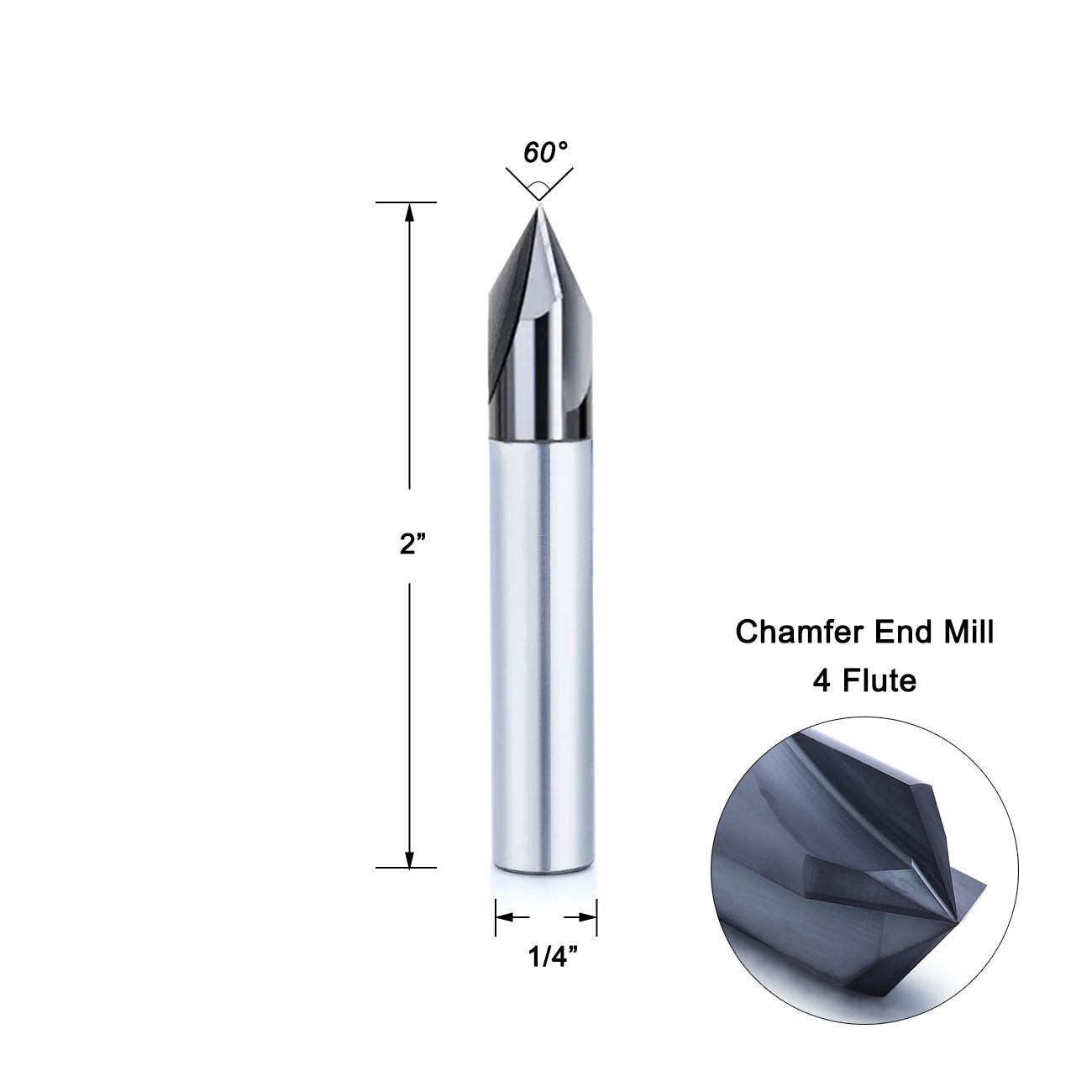

Carbide Chamfer End Mill, 60/90 Degree, Carving Bits, V Groove, 4 Flute AlTiN Coating for Alloy Steels, Hardened Steels-Imperial

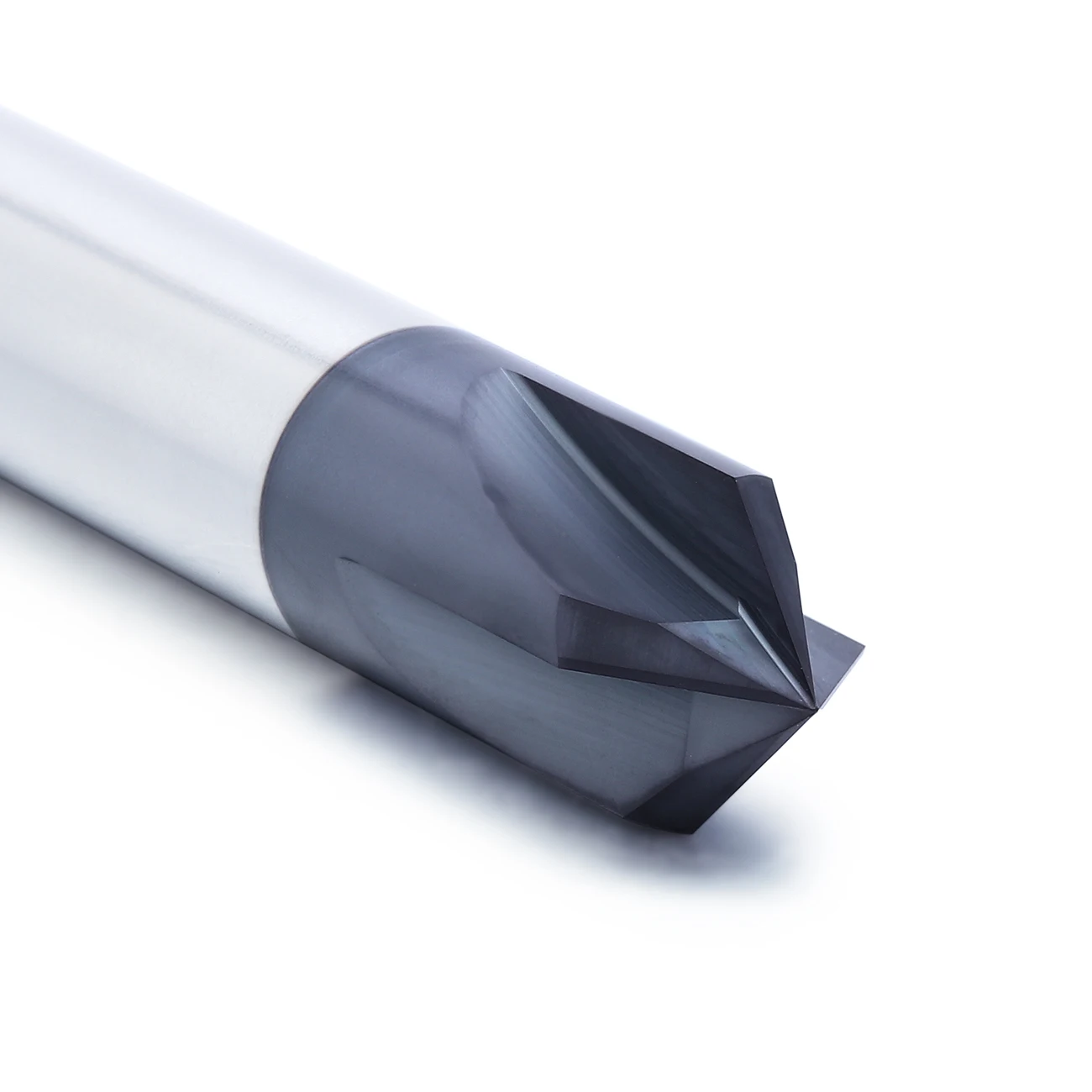

- Material: This end mill is made of high-quality tungsten carbide powder and cobalt, which has extraordinary toughness, durability, and machinability, improving the tool's service life while keeping the end mill sharp.

- AlTiN Coating: Titanium aluminum nitride (AlTiN) coating lubricates the end mill for stability at high temperature and superior wear resistance at high cutting speeds, offering better heat resistance than TiAlN, TiN or TiCN coatings.

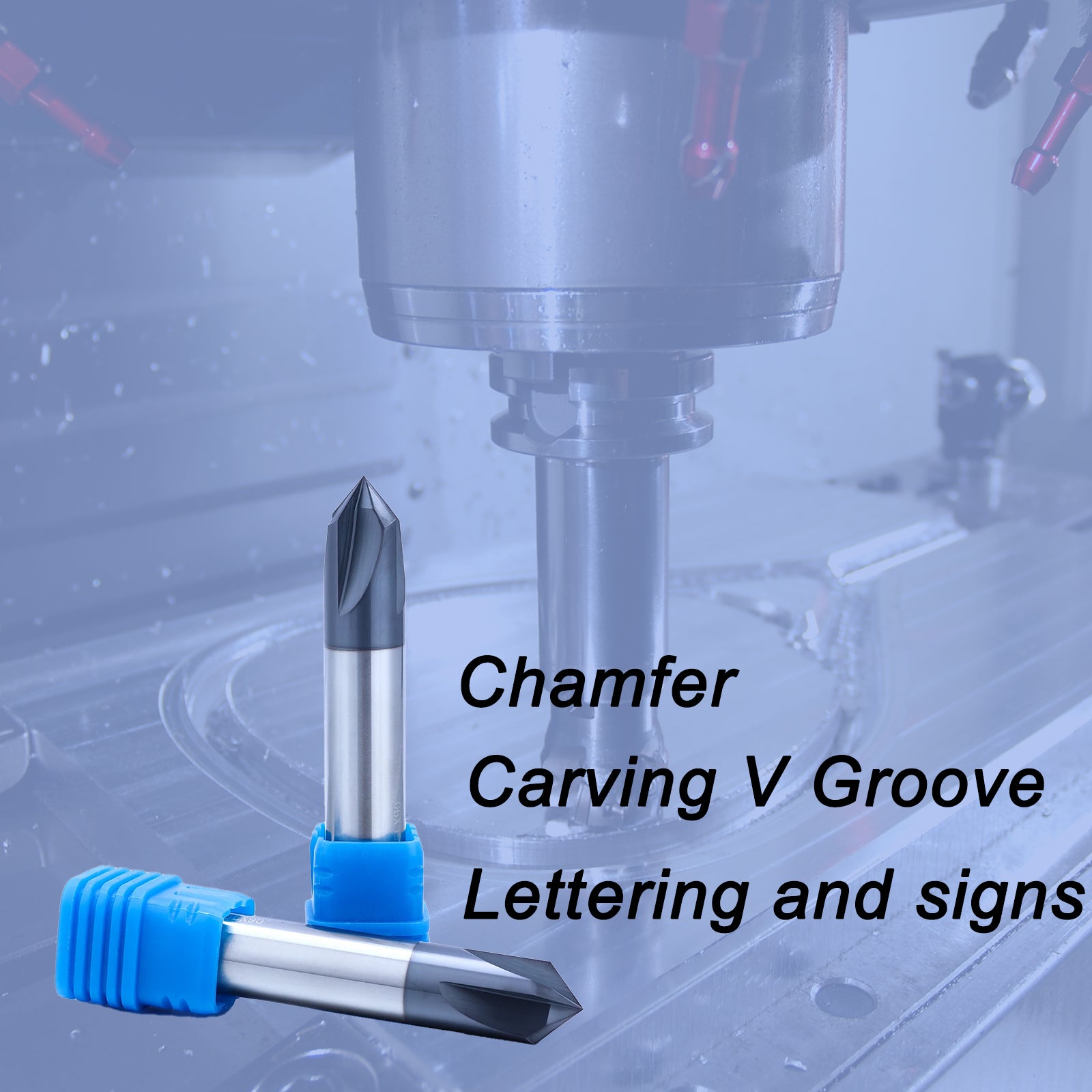

- Distinctive Design: This end mill is designed for multiple purposes, such as chamfering, centering, deburring and engraving V grooves.

- APPLICATION: Applicable with steels, carbon steels, alloy steels, copper, copper alloys, cast iron,etc.

Pairs well with

Carbide Chamfer End Mill, 60/90 Degree, Carving Bits, V Groove, 4 Flute AlTiN Coating for Alloy Steels, Hardened Steels-Imperial

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays.

-

Shipping Information

Use this text to answer questions in as much detail as possible for your customers.

-

Customer Support

Use this text to answer questions in as much detail as possible for your customers.

-

FAQ’s

Use this text to answer questions in as much detail as possible for your customers.

-

Contact Us

Use this text to answer questions in as much detail as possible for your customers.

PRODUCT HIGHLIGHTS

Ultra-high hardness and wear resistance: The carbide substrate provides extremely high hardness and wear resistance. With the AlTiN coating, it can maintain a sharp cutting edge under high temperature and high-speed cutting, greatly extending the tool life.

Advantages of AlTiN coating: The AlTiN coating has excellent thermal hardness and oxidation resistance, stable cutting, and reduced adhesive wear.

4-edge spiral design: The evenly distributed 4-edge spiral groove design has a more balanced cutting force distribution, reduces vibration and radial runout, and significantly improves surface finish and processing accuracy.

Multi-scenario application: It is widely used in various processing methods such as milling grooves, face milling, and intermittent cutting. It is compatible with various materials such as alloy steel, carbon steel, and cast iron to meet the processing needs of complex parts.

APPLICATION SCENARIOS

Mold manufacturing: Efficiently remove hard cavity materials to ensure mold cavity accuracy and surface quality. High temperature and wear resistance, significantly extending the service life.

Mechanical mass production: Maintain stability under high cutting loads, suitable for large-scale and continuous production, and reduce the frequency of tool changes.