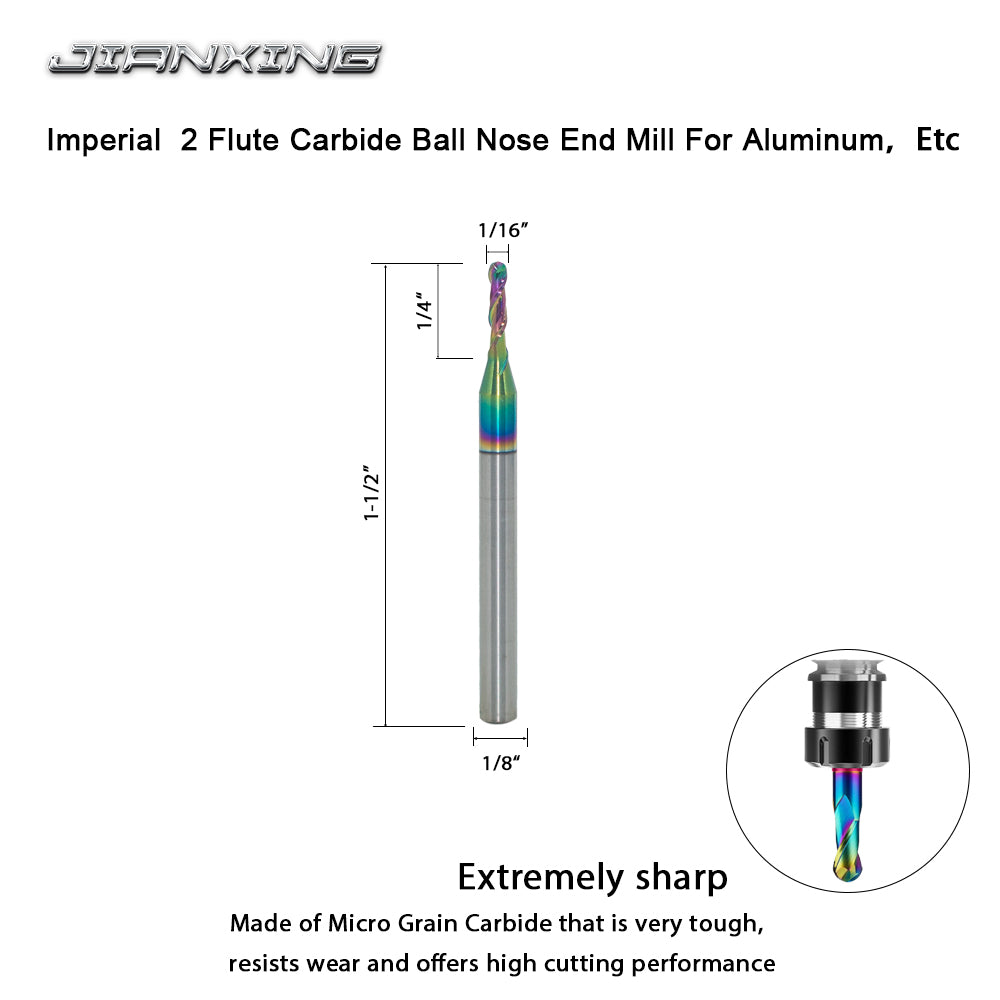

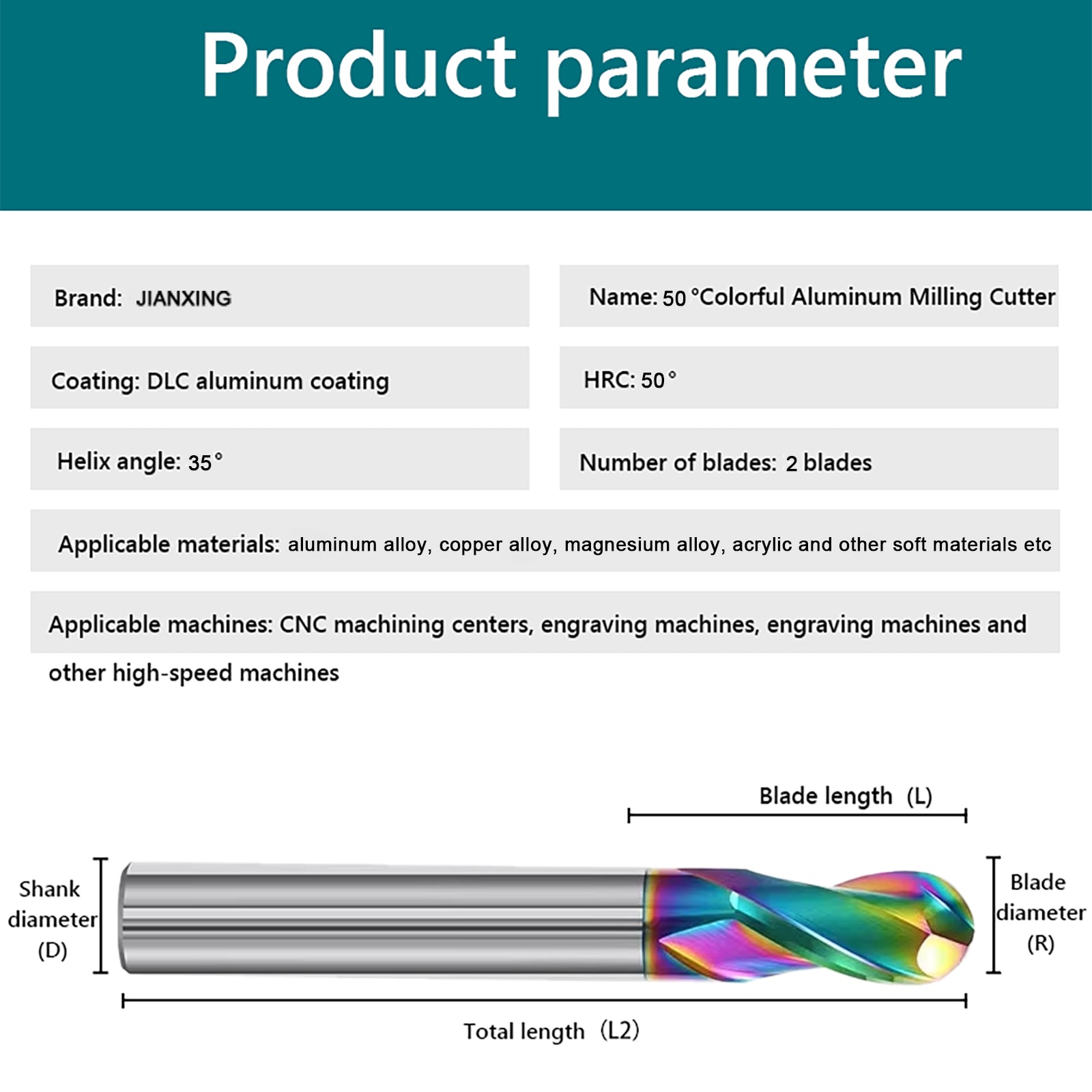

Carbide Ball Nose End Mill for Aluminum, Copper Alloy, Plastic, 2 Flute DLC Coating-Imperial

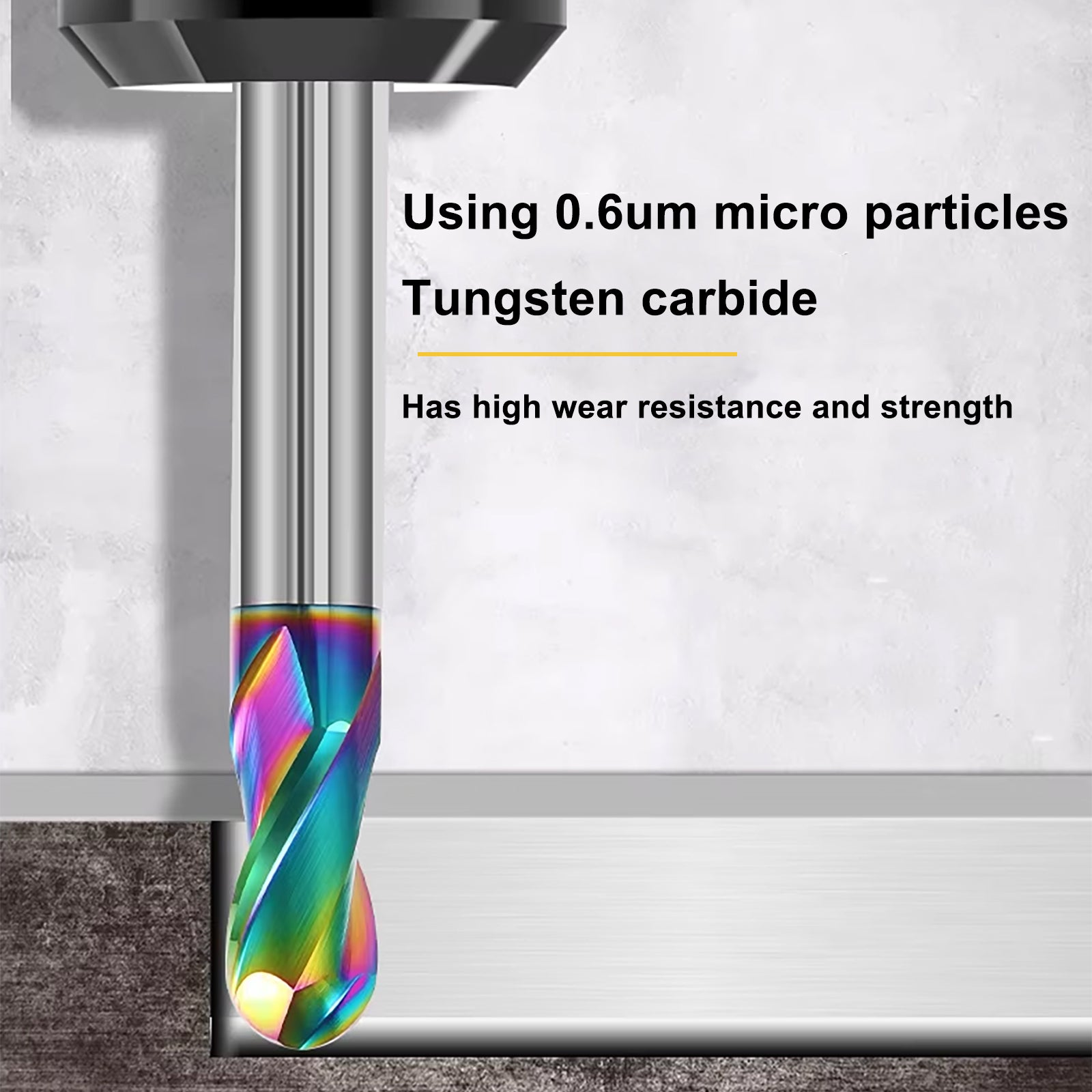

- Material : Use Ultrafine Grain Tungsten-Carbide Steel Matrix,For Aluminum Alloy And Copper Alloy, Magnesium Alloy, Zinc Alloy, Plastic, Etc

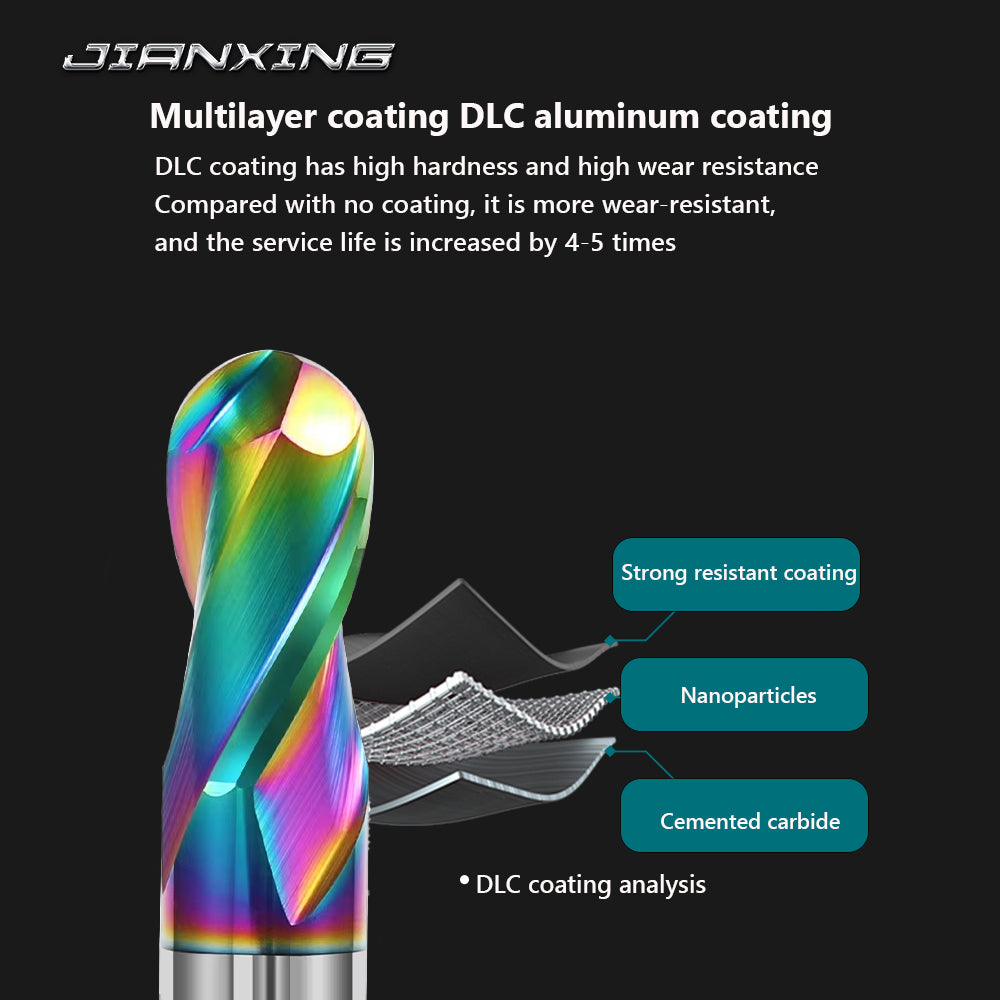

- Dlc Coating : Dlc(Diamond-Like Carbon) Coating Has Ultra-High Hardness,Low Friction Coefficient, High Temperature Resistance, Good Electrical Insulation, Chemical Barrier, High Thermal Conductivity, Ultra-High Anti-Blocking Performance.

- Design Feature : Double Flute Design, With Excellent Cutting Performance, While Leaving A Smooth Surface On The Workpiece.

- Efficiency: For Processing Complex Curved Surfaces Or Three-Dimensional Shapes Of Workpieces, It Can Effectively Reduce The Number Of Tool Changes And Improve Efficiency.

Pairs well with

Carbide Ball Nose End Mill for Aluminum, Copper Alloy, Plastic, 2 Flute DLC Coating-Imperial

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays.

-

Shipping Information

Use this text to answer questions in as much detail as possible for your customers.

-

Customer Support

Use this text to answer questions in as much detail as possible for your customers.

-

FAQ’s

Use this text to answer questions in as much detail as possible for your customers.

-

Contact Us

Use this text to answer questions in as much detail as possible for your customers.

Solid Carbide 2-Flute Ball Nose End Mill, Designed for High-Speed Milling of Aluminum, Extra-Long Tool Life

Specially designed for high-speed milling, this solid carbide 2-flute ball nose end mill combines advanced coatings and optimized geometry for exceptional durability. Whether for mass production or precision work, this tool provides consistent performance, extending tool life and boosting productivity.

Super Wear-Resistant DLC Coated Solid Carbide 2-Flute Ball Nose End Mill, Boosts Aluminum Machining Efficiency

Featuring a DLC coating that greatly enhances wear resistance and corrosion resistance, this 2-flute ball nose end mill is ideal for aluminum and light metal machining. It significantly improves cutting efficiency, reduces tool change frequency, and helps lower production costs.